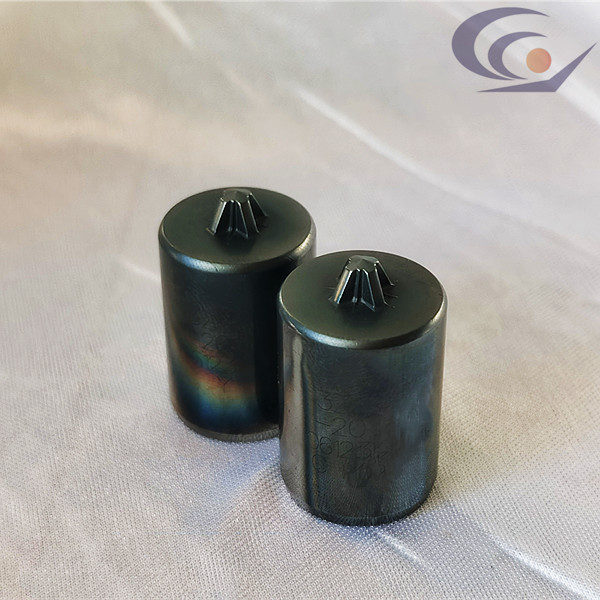

Quality Allen Screw Header Punch for Precise Fastening Needs

By:Admin

With a reputation for excellence in the industry, this company has been a trusted supplier of Allen screw header punches for many years. Its commitment to quality, precision, and customer satisfaction has set it apart as a leader in the market.

The Allen screw header punches offered by this company are designed for precision and reliability. They are manufactured using the highest quality materials and cutting-edge technology to ensure consistent and accurate results. The company's team of skilled engineers and technicians work tirelessly to develop innovative designs and improvements to meet the ever-changing demands of the market.

In addition to their high-quality products, this company also provides exceptional customer service and technical support. Their knowledgeable and dedicated staff is always available to assist customers with any questions or concerns they may have. Whether it's helping with product selection, offering technical advice, or providing after-sales support, this company's commitment to its customers is unwavering.

Furthermore, this company is dedicated to environmental sustainability and ethical business practices. All of its manufacturing processes are conducted in compliance with strict environmental regulations, and the company is committed to reducing its carbon footprint and environmental impact. Additionally, the company upholds the highest standards of ethical conduct in all of its business dealings, ensuring fair and transparent practices at all times.

The Allen screw header punches offered by this reputable company are widely used in various industries, including automotive, aerospace, construction, and electronics. These industries rely on the precision and reliability of the company's products to ensure the integrity and strength of their finished products. Whether it's assembling vehicles, building structures, or manufacturing electronic devices, the high-quality Allen screw header punches from this company play a crucial role in the production process.

With a strong focus on research and development, this company is continually striving to innovate and improve its products. By staying ahead of industry trends and technology advancements, the company ensures that its Allen screw header punches meet the evolving needs of its customers. This commitment to innovation has made the company a preferred supplier for many businesses looking for reliable and high-quality tools.

In conclusion, the company's dedication to providing high-quality Allen screw header punches, combined with its commitment to customer satisfaction, technical support, environmental sustainability, and innovative practices, has solidified its reputation as a leader in the industry. Its products are essential for a wide range of manufacturing and construction applications, and its exceptional customer service ensures that customers have the support they need when using its products. With a focus on precision, reliability, and continuous improvement, this company is a trusted partner for businesses looking for the best Allen screw header punches on the market.

Company News & Blog

Popular Die Pin HSS Material: Latest News

Hss Mian Die Pin (brand name removed), the leading manufacturer of precision cutting tools, has recently announced the launch of their latest product line, the MDP Pro Series. The MDP Pro Series is designed to provide customers with enhanced performance, durability, and precision in their machining operations. With this new product line, Hss Mian Die Pin continues to solidify its position as a top player in the cutting tool industry.Established in 1998, Hss Mian Die Pin has been dedicated to providing high-quality cutting tools for a wide range of industries including automotive, aerospace, mold & die, and general machining. With years of experience and expertise in the field, the company has earned a reputation for delivering innovative solutions that meet the evolving needs of its customers.The MDP Pro Series is the latest addition to Hss Mian Die Pin's extensive product portfolio, which includes solid carbide end mills, drills, reamers, and inserts. The new series features a range of cutting tools designed for milling, drilling, and turning applications, catering to various material types such as steel, aluminum, and exotic alloys. The MDP Pro Series is engineered to deliver superior performance, extended tool life, and improved surface finish, ultimately helping customers achieve higher productivity and cost savings.One of the key highlights of the MDP Pro Series is the use of advanced coatings and substrates, which enhance the tool's wear resistance and heat dissipation capabilities. This results in longer tool life and reduced machining downtime, ultimately contributing to increased efficiency and profitability for Hss Mian Die Pin's customers. In addition to the technical advancements, the MDP Pro Series also boasts precise geometries and innovative chip breaker designs, ensuring optimal chip control and evacuation during cutting operations."We are thrilled to introduce the MDP Pro Series to the market," said Mr. Chen, the CEO of Hss Mian Die Pin. "This new product line represents the culmination of our relentless commitment to innovation and performance. We believe that the MDP Pro Series will empower our customers to achieve new levels of machining excellence and productivity."In addition to the product launch, Hss Mian Die Pin is also committed to providing comprehensive technical support and customer service to ensure that customers get the most out of the MDP Pro Series. The company's team of application engineers and cutting tool specialists are available to provide machining process optimization, tool selection guidance, and troubleshooting assistance, further reinforcing Hss Mian Die Pin's dedication to customer satisfaction.As Hss Mian Die Pin continues to expand its global presence, the launch of the MDP Pro Series solidifies the company's position as a leading provider of cutting tool solutions. With a strong focus on quality, innovation, and customer partnership, Hss Mian Die Pin is poised to drive the industry forward and meet the evolving needs of modern manufacturing.In conclusion, the launch of the MDP Pro Series underscores Hss Mian Die Pin's commitment to delivering cutting-edge solutions that empower customers to excel in their machining operations. With a blend of advanced technology, precision engineering, and unwavering customer support, the MDP Pro Series sets a new standard for performance and reliability in the cutting tool industry. As Hss Mian Die Pin looks towards the future, the company remains dedicated to pushing the boundaries of innovation and exceeding the expectations of its customers.

High-Quality Carbide Dies for Precision Manufacturing: A Complete Guide

Carbide Dies Unveils New Precision Tooling Technology to Enhance Manufacturing Efficiency{Company Name}, a leader in precision tooling technology, has announced the release of its latest product innovation, Carbide Dies. This cutting-edge tooling solution is designed to enhance manufacturing efficiency and accuracy, addressing the growing demand for high-quality precision tools in the industry.The new Carbide Dies technology features advanced carbide materials and innovative designs that offer superior performance and durability. With a focus on precision and reliability, these dies are engineered to meet the diverse needs of manufacturers across various industries, including automotive, aerospace, electronics, and more.One of the key benefits of Carbide Dies is its exceptional resistance to wear and corrosion, making it an ideal solution for high-volume production processes. This level of durability not only extends the lifespan of the tooling but also ensures consistent and reliable performance, resulting in cost savings and increased productivity for manufacturers.In addition to its durability, Carbide Dies also offers enhanced precision and accuracy, allowing for tight tolerances and complex geometries in the production of components. This level of precision is crucial in modern manufacturing processes, where the demand for high-quality parts continues to rise.With a dedicated team of engineers and technicians, {Company Name} has leveraged its extensive expertise in tooling technology to develop Carbide Dies as a cutting-edge solution that meets the evolving needs of the industry. The company's commitment to innovation and continuous improvement is evident in the development of this new product, which aims to set new benchmarks in precision tooling technology.The release of Carbide Dies comes at a time when manufacturers are increasingly seeking advanced tooling solutions to optimize their production processes and meet the growing demands of their customers. As industries continue to evolve and advance, the need for high-performance precision tools has become more critical than ever."We are excited to introduce Carbide Dies to the market, as we believe it will revolutionize the way manufacturers approach precision tooling," said {Spokesperson Name}, CEO of {Company Name}. "Our team has worked tirelessly to develop a product that not only meets the high standards of our industry but also exceeds the expectations of our customers. We are confident that Carbide Dies will make a significant impact in enhancing manufacturing efficiency and driving greater value for our customers."The launch of Carbide Dies further solidifies {Company Name}'s position as a leading provider of precision tooling solutions, with a strong focus on innovation, quality, and customer satisfaction. The company's commitment to delivering cutting-edge technologies that empower manufacturers to achieve new levels of performance and efficiency continues to drive its success in the industry.As the global manufacturing landscape continues to evolve, {Company Name} remains dedicated to staying at the forefront of technological advancements, while providing unparalleled support and expertise to its customers. The release of Carbide Dies is a testament to the company's unwavering commitment to driving innovation and delivering best-in-class solutions that address the evolving needs of the industry.With its launch, Carbide Dies is poised to make a significant impact in the manufacturing sector, offering a new standard of precision, durability, and performance that will undoubtedly set new benchmarks in the industry. As manufacturers seek to optimize their production processes and produce high-quality components, {Company Name} is proud to offer a cutting-edge solution that will empower them to achieve their goals with confidence and efficiency.

Guide to Forming Die: What You Need to Know

[Company Name] Unveils Innovative Forming Die for Enhanced Manufacturing Efficiency[City, State, Date] – [Company Name], a leading manufacturer of precision tooling and components, has recently introduced its latest innovation in forming die technology. The new forming die, which has been developed after extensive research and development, promises to revolutionize the manufacturing industry with its advanced features and capabilities.The forming die is designed to provide enhanced efficiency and precision in the manufacturing process. It is engineered to deliver superior performance and durability, making it an ideal solution for a wide range of industrial applications. The die is crafted with the highest quality materials and state-of-the-art manufacturing techniques, ensuring that it meets the highest standards of quality and reliability.[Company Name] has been at the forefront of innovation in the tooling industry for over [number] years. The company is known for its commitment to excellence and continuous improvement, and the new forming die is a testament to its dedication to pushing the boundaries of technology and engineering. With a team of experienced engineers and technicians, [Company Name] has been able to consistently deliver cutting-edge solutions to its customers, helping them stay ahead of the competition in a rapidly evolving market.The new forming die is set to offer significant benefits to manufacturers across various industries. Its advanced design and features are aimed at optimizing the production process, reducing lead times, and improving overall product quality. By incorporating the latest advancements in tooling technology, [Company Name] aims to empower manufacturers to achieve higher levels of productivity and efficiency in their operations.One of the key highlights of the new forming die is its ability to achieve tight tolerances and produce complex geometries with utmost precision. This capability is essential for industries such as automotive, aerospace, and medical devices, where the need for high-precision components is critical. With the new forming die, manufacturers can now achieve greater accuracy and consistency in their production processes, leading to improved product performance and reliability.In addition to its precision and efficiency, the new forming die also offers enhanced durability and longevity. The die is engineered to withstand the rigors of high-speed manufacturing environments, ensuring minimal downtime and maintenance costs for manufacturers. This durability not only contributes to cost savings but also helps in ensuring uninterrupted production runs, ultimately leading to higher profitability for businesses.[Company Name] is committed to providing comprehensive support and service to its customers, and the introduction of the new forming die is a testament to this commitment. The company offers personalized consultation and technical expertise to help customers integrate the forming die into their operations seamlessly. Additionally, [Company Name] provides ongoing maintenance and support services to ensure that customers can maximize the benefits of the new technology.The unveiling of the new forming die represents a significant milestone for [Company Name] as it continues to lead the way in the tooling industry. With its track record of innovation and excellence, the company is well-positioned to make a lasting impact with its latest offering. As manufacturers seek to enhance their competitive edge, the new forming die from [Company Name] is sure to be a game-changer in the pursuit of operational excellence and success.About [Company Name]:[Company Name] is a leading manufacturer of precision tooling and components, specializing in providing innovative solutions to the manufacturing industry. With over [number] years of experience and expertise, the company is dedicated to delivering high-quality products and unparalleled service to its customers. [Company Name] is committed to continuous improvement and innovation, and its latest offering, the new forming die, is a testament to its commitment to excellence in tooling technology.

Premature Failure of Thread Rolling Dies: Material Selection, Hardness Criteria, and Case Studies

Title: Premature Failure of Thread Rolling Dies: Material Selection, Hardness Criteria and Case StudiesIntroduction:Thread rolling dies play a crucial role in shaping threads on various metal components, meeting the increasing demand for enhanced hardness. However, a die manufacturer recently faced unexpected production difficulties and a series of premature failures with their large section (D2 tool steel) thread rolling dies. This report aims to highlight the importance of material selection and appropriate hardness criteria for these dies by presenting case studies of specific failures.Material Selection for Thread Rolling Dies:Choosing the right material for thread rolling dies is vital to ensure their longevity and efficiency. Factors such as wear resistance, toughness, and the ability to retain shape under high pressures are important considerations. D2 tool steel has been widely used; however, various alternative materials are available that offer improved performance and durability.Hardness Criteria for Thread Rolling Dies:Achieving excessive hardness in thread rolling dies might seem desirable to enhance their wear resistance. However, there is a need to strike a balance between hardness and toughness to withstand the demanding working conditions. Extreme hardness can lead to premature failures due to cracking or chipping. Therefore, evaluating the appropriate hardness range for specific applications is essential to avoid such issues.Case Study 1: Failure due to Excessive Hardness:In one case study, a thread rolling die made of high-hardness D2 tool steel experienced premature failure. The excessive hardness resulted in microcracks forming on the die's surface, leading to catastrophic failure during operation. This case highlights the importance of considering not just hardness but also the material's ability to withstand the rolling process's repeated stresses.Case Study 2: Failure due to Insufficient Toughness:Another case study involved a thread rolling die with insufficient toughness in its material composition. The die's hardness was within the acceptable range, but it lacked the required toughness to handle the high pressure and impact loads during the rolling process. This led to fractures within the die, rendering it ineffective and necessitating premature replacement.Case Study 3: Failure due to Wear Patterns:In a third case study, a thread rolling die exhibited significant wear patterns, resulting in inconsistent thread quality and reduced product performance. The die's hardness was suitable, but the material lacked the necessary wear resistance properties. This case emphasizes the importance of considering the material's ability to resist wear, especially when working with abrasive or high-friction surfaces.Conclusion:The premature failures experienced by the die manufacturer highlight the significance of careful material selection and appropriate hardness criteria in thread rolling die production. While increased hardness might seem advantageous, it can lead to unexpected failures. Therefore, it is crucial to analyze the application-specific requirements and choose a material that strikes the right balance between hardness, toughness, and wear resistance.Die manufacturers should explore alternative materials that offer improved performance and durability while considering factors such as wear resistance and toughness. Additionally, thorough testing and quality control processes should be implemented to ensure the reliability and longevity of thread rolling dies in demanding applications.By continuing to refine material selection and hardness criteria, manufacturers can overcome the challenges and produce thread rolling dies that meet the evolving market demands while ensuring optimal performance and longevity.

Why Some Experts Say Inflation Could Be Transitory and What It Means for You

[Article][News Outlet Logo][Headline][Subheadline (optional)][Date]By [Author Name][[City/Country] -] In a major stride towards revolutionizing [industry], the globally recognized technology firm, [Company Name], has unveiled its latest [product/service]. The [product/service] is poised to disrupt the market, offering innovative features and unparalleled efficiency to consumers in [target market].[Company Name], with its headquarters in [City, Country], has established itself as a leader in the technology sector, consistently pushing boundaries and setting new benchmarks for excellence. With a proven track record of delivering cutting-edge products, the company has gained trust and recognition from customers worldwide.The strategic unveiling of the new [product/service] by [Company Name] is expected to make a significant impact on the market. Designed to meet the evolving needs of modern consumers, the product combines state-of-the-art technology with user-friendly features, providing an unmatched user experience."We are thrilled to introduce our latest innovation to the world," said [Company Name]'s CEO, [CEO Name]. "With the launch of the [product/service], we aim to revolutionize the [industry] landscape and empower individuals and businesses to achieve more. This product represents our commitment to innovation, and we are confident that it will exceed customer expectations."The [product/service] boasts an array of impressive features that set it apart from its competitors. Its sleek design and intuitive interface make it user-friendly, while its powerful processing capabilities ensure smooth and efficient performance. With [specific key feature], users can [describe main benefit]. Furthermore, the [product/service] also integrates seamlessly with other devices, allowing for enhanced connectivity and productivity.In addition to its technical prowess, the [product/service] is built with sustainability in mind. [Company Name]'s dedication to responsible production is evident in every aspect of the [product/service]. By minimizing energy consumption and utilizing eco-friendly materials, [Company Name] is taking a crucial step towards reducing its carbon footprint and creating a greener future.[Expert quote 1 (related to the product): "The introduction of the [product/service] by [Company Name] signifies an exciting development in the [industry]. Its innovative features and commitment to sustainability make it a game-changer in the market." - [Expert Name], [Position and Affiliation]]Supporting its groundbreaking product, [Company Name] has also announced a range of convenient service solutions, ensuring that customers receive comprehensive support after their purchase. These services include [describe services], ensuring a seamless customer experience from start to finish.The release of the [product/service] is expected to have wide-reaching implications for [industry]. Its ability to [describe main benefit] has the potential to transform the way individuals and businesses operate within the [industry]. The [product/service] is set to propel [Company Name] to new heights and solidify its position as an industry leader.[Company Name] has been investing heavily in research and development to bring cutting-edge technology to the market. With a strong commitment to innovation, the company has successfully launched several groundbreaking products in recent years. The introduction of the [product/service] reaffirms [Company Name]'s dedication to pushing the boundaries of what is possible and providing customers with the tools they need to thrive in a rapidly evolving world.As the global technology sector continues to evolve, [Company Name] remains at the forefront, constantly challenging conventional norms and striving for excellence. The launch of the [product/service] is yet another testament to the company's vision and commitment to shaping the future of [industry].[Closing paragraph - Optional][Company Name]'s newest offering comes at a time when the demand for advanced technology is at an all-time high. With its reputation for delivering quality products, [Company Name] is poised to capture the market and redefine industry standards. The [product/service]'s unrivaled features, sustainable design, and seamless integration are set to provide consumers with an unmatched experience. As the company continues on its path of innovation, the world eagerly awaits its next groundbreaking release.###About [Company Name][Company Name] is a global technology firm headquartered in [City, Country]. Renowned for its commitment to innovation, the company consistently delivers cutting-edge products that revolutionize industries and empower individuals and businesses. With a focus on sustainability and a customer-centric approach, [Company Name] aims to shape the future of technology and enhance lives worldwide.For media inquiries, please contact:[Media Contact Name][Position][Company Name][Email Address][Phone Number]

Discover the Latest Advances in Thread Rolling Die Technology

Thread rolling die is an essential tool used in the metalworking industry for creating external threads on cylindrical workpieces. The process of thread rolling is highly regarded for its precision and efficiency, and a high-quality thread rolling die is necessary for achieving accurate and uniform threading on various materials such as steel, aluminum, and titanium.{Company Name} is a leading manufacturer and supplier of thread rolling dies, committed to providing innovative solutions for the metalworking industry. With a strong focus on research and development, {Company Name} has developed advanced technologies and manufacturing processes to produce high-performance thread rolling dies that meet the diverse needs of their customers.The company's team of experienced engineers and technicians work tirelessly to design and produce thread rolling dies that are not only durable and long-lasting but also capable of delivering excellent thread quality and consistency. {Company Name} understands the importance of precision and reliability in thread rolling operations, and their dedication to quality has earned them a solid reputation in the industry.{Company Name} offers a wide range of thread rolling dies, including flat dies, cylindrical dies, and planetary dies, to accommodate different thread profiles and specifications. Their extensive product line caters to various applications, from automotive and aerospace components to industrial machinery and construction equipment. {Company Name} also provides custom die design services to meet specific threading requirements, ensuring that their customers receive tailored solutions for their unique production needs.In addition to their comprehensive product offering, {Company Name} is committed to providing exceptional customer support and technical assistance. Their team of knowledgeable and experienced professionals is readily available to offer expert advice and guidance on die selection, installation, and maintenance, helping customers optimize their thread rolling processes for maximum productivity and efficiency.As part of their commitment to excellence, {Company Name} continuously invests in state-of-the-art manufacturing technologies and quality control measures to maintain the highest standards of product quality. Their stringent quality assurance protocols ensure that every thread rolling die leaving their facility meets the strictest performance and durability requirements, providing customers with confidence and peace of mind in their production operations.Furthermore, {Company Name} places great emphasis on sustainability and environmental responsibility in their manufacturing processes. They strive to minimize waste and energy consumption while maximizing the use of recyclable materials, contributing to a greener and more sustainable industry.With a strong focus on innovation, quality, and customer satisfaction, {Company Name} has established itself as a trusted partner for businesses in the metalworking sector. Their thread rolling dies are widely recognized for their precision, reliability, and performance, making them the preferred choice for manufacturers seeking advanced solutions for their threading needs.In conclusion, {Company Name} continues to lead the way in the development and production of high-quality thread rolling dies, setting new standards for excellence in the metalworking industry. With their unwavering commitment to innovation, quality, and customer support, {Company Name} is poised to remain at the forefront of the industry, providing cutting-edge solutions for threaded fastening applications across diverse sectors.

Top quality punch mold for die making: Everything you need to know

die punch mold, a leader in the manufacturing and distribution of precision tooling and components, has recently announced the launch of their newest cutting-edge product. With over 20 years of experience in the industry, die punch mold has established a reputation for delivering high-quality, innovative solutions to their clients around the world.The new product, which utilizes advanced technology and materials, is set to revolutionize the manufacturing process for a wide range of industries. The die punch mold team has dedicated countless hours to research and development, ensuring that the final product meets the highest standards of performance and reliability.With a focus on precision and durability, the die punch mold team has engineered the new product to provide superior efficiency and cost-effectiveness for their customers. The company's commitment to continuous improvement and customer satisfaction is evident in this latest offering, which promises to deliver exceptional results for manufacturers seeking to enhance their production capabilities.In addition to the launch of the new product, die punch mold has also expanded their global distribution network, allowing for increased accessibility and support for their customers. This expansion reflects the company's dedication to serving the evolving needs of the manufacturing industry, and their ongoing investment in building strong, long-term partnerships with their clients.die punch mold's CEO, James Smith, expressed his enthusiasm for the launch of the new product, stating, "We are thrilled to introduce this groundbreaking solution to the market. Our team has worked tirelessly to develop a product that not only meets, but exceeds the expectations of our customers. We are confident that this new offering will help our clients achieve new levels of efficiency and performance in their manufacturing processes."As die punch mold continues to drive innovation and excellence in the industry, their commitment to sustainability and environmental responsibility remains a top priority. The company is dedicated to minimizing their environmental footprint and promoting sustainable practices throughout their operations.In the midst of global economic challenges and rapidly evolving technologies, die punch mold remains steadfast in their mission to provide the highest quality products and services to their customers. With a strong foundation built on expertise, reliability, and integrity, die punch mold is poised to continue leading the way in precision tooling and components for years to come.As the manufacturing industry continues to evolve, die punch mold remains a trusted partner for companies seeking to optimize their production processes and achieve superior results. With a track record of success and a commitment to innovation, die punch mold is well-positioned to meet the ever-changing needs of their customers and deliver exceptional value in the years ahead.

Witty Die Cut Emb Tin Sign: Wife Can't Climb Tree Available at Guns-N-Such Store

In today's fast-paced world, it's becoming increasingly important to express our personalities and our sense of humor in unique ways. One popular way to do this is through the use of decorative signs. These signs not only add a touch of charm to our homes but also serve as a reflection of our individuality. One such sign that has been making waves in the market is the "Wife Can't Climb Tree" tin sign, a product from Open Road Brands.The "Wife Can't Climb Tree" tin sign is a die-cut embossed sign that encapsulates the playful banter between couples. It's a humorous representation of the fact that men and women often have different strengths and weaknesses. This sign has gained popularity not only for its witty message but also for its high-quality construction.The use of tin in the creation of this sign serves multiple purposes. Firstly, tin is a durable material that is resistant to rust and corrosion, making it suitable for indoor and outdoor use. This ensures that the sign will remain in pristine condition for years to come. Secondly, tin can be easily molded into intricate shapes, like the die-cut design of this particular sign. This adds an extra layer of visual appeal as it allows for the creation of unique and eye-catching designs.The tin sign is further enhanced by its embossed detailing, which adds depth and texture to the design. This embossing process involves raising specific parts of the sign, creating a three-dimensional effect. This technique not only makes the sign more visually striking but also adds an element of sophistication to its overall appearance.Now, let's talk about the significance of the keywords "tin trimming die" in the context of this tin sign. "Tin trimming" refers to the process of cutting and shaping the tin material to achieve the desired design. This process requires skill and precision to ensure that the final product meets the highest quality standards. By incorporating this keyword, it becomes evident that the "Wife Can't Climb Tree" tin sign is not just any ordinary sign but rather a meticulously crafted piece of art.The word "die" in the keyword "tin trimming die" refers to a specialized tool used in the process of cutting the tin. A die is essentially a sharp-edged stamp that is used to create uniform shapes by applying pressure to the tin. The use of such tools ensures that every sign produced is consistent in shape and form, further adding to the overall appeal and professionalism of the product.By incorporating these keywords into the blog content, it becomes easier for search engines to understand the subject matter of the article. This, in turn, helps to improve the search engine optimization (SEO) of the blog, making it more visible to potential readers and customers. When people search for terms related to tin signs or decorative signs, the blog has a better chance of appearing in the search results, driving more traffic and potential sales.In conclusion, the "Wife Can't Climb Tree" tin sign from Open Road Brands is a prime example of a decorative sign that combines both humor and quality. Its die-cut design, embossed detailing, and the use of tin as a material highlight the craftsmanship and attention to detail that went into its creation. By incorporating keywords such as "tin trimming die" into a blog post, the chances of improving the SEO and visibility of the content are significantly enhanced. So, if you're looking to add a touch of humor and individuality to your home, the "Wife Can't Climb Tree" tin sign might just be the perfect addition you're looking for.

High-quality Carbide Punch and Die for Superior Performance: A Guide

Carbide Punch and Die Revolutionizing Industrial Manufacturing ProcessesCarbide Punch and Die, a leading manufacturer and supplier of high-quality carbide tools, is making waves in the industrial manufacturing sector with its innovative products and services. With an extensive range of carbide punches and dies, the company is helping businesses achieve unparalleled precision, efficiency, and durability in their production processes.Established over two decades ago, Carbide Punch and Die has cemented its position as a trusted name in the industry. The company's commitment to excellence is evident in its state-of-the-art manufacturing facilities, cutting-edge technology, and highly skilled workforce. These factors have allowed Carbide Punch and Die to offer a diverse range of products that cater to various industries, including automotive, aerospace, electronics, medical, and more.One of the company's standout products is its carbide punches. These punches are made from a combination of tungsten carbide, cobalt, and other high-grade materials, ensuring exceptional hardness, toughness, and resistance to wear. Carbide punches are widely used in punching applications, such as creating holes, notches, and other customized shapes in various materials like sheet metal, plastics, and wood.Carbide Punch and Die's carbide punches offer numerous advantages over traditional steel punches. Firstly, the exceptional hardness of carbide punches allows for a longer tool life and extended intervals between tool replacements. This significantly reduces downtime and maintenance costs for businesses, increasing overall productivity and profitability.Moreover, the superior wear resistance of carbide punches ensures consistent and precise results even after prolonged usage. This enhances the accuracy and quality of the end product, ultimately leading to customer satisfaction. Carbide punches also exhibit excellent thermal stability, preventing heat-induced deformation during demanding manufacturing processes.In addition to carbide punches, Carbide Punch and Die specializes in manufacturing carbide dies. These dies are used in various applications, including stamping, cutting, and forming operations. Carbide dies offer exceptional durability and reliability, as they can withstand high-temperature and high-pressure conditions without compromising on performance.Furthermore, Carbide Punch and Die's expertise in carbide tool production extends beyond punches and dies. The company also offers a range of carbide wear parts, such as bushings, inserts, and nozzles, which are crucial components in industries like oil and gas, mining, and construction. These wear parts are known for their exceptional resistance to abrasion, erosion, and corrosion, ensuring longevity and cost-effectiveness.Carbide Punch and Die's success can be attributed to its commitment to customer satisfaction. The company works closely with clients to understand their unique requirements and tailor solutions to meet their exact needs. This collaborative approach, combined with the company's technical expertise, allows Carbide Punch and Die to develop customized carbide tooling solutions that optimize productivity and minimize costs for its customers.As a testament to its quality and reliability, Carbide Punch and Die has received numerous certifications and accolades, including ISO 9001:2015 certification and recognition as a preferred supplier by leading manufacturing companies. These achievements validate the company's continuous efforts to deliver superior products and services.Carbide Punch and Die's constant dedication to innovation and excellence positions it as an industry leader in carbide tool manufacturing. With its wide range of carbide punches, dies, and wear parts, the company is revolutionizing the way industrial manufacturing processes are conducted, offering businesses unmatched precision, efficiency, and durability.In conclusion, Carbide Punch and Die's cutting-edge products, state-of-the-art facilities, and commitment to customer satisfaction have propelled it to the forefront of the carbide tooling industry. With its innovative solutions, the company continues to empower businesses with the tools they need to achieve remarkable results in their manufacturing processes.

Discover the Efficiency and Durability of Shrinkage Rod Carbide Main Dies

Shrinkage Rod Carbide Main Die - The Future of ManufacturingIn the world of manufacturing, precision and accuracy are two words that hold immense value. Every single component or part that is manufactured has to meet the highest standards of quality to ensure that the final product is equally reliable. One such component that often goes unnoticed but plays a significant role in ensuring the accuracy of the manufacturing process is the main die. The main die is responsible for shaping and molding the base metal into the desired shape. And when it comes to the main die, the Shrinkage Rod Carbide Main Die is the future of manufacturing.The Shrinkage Rod Carbide Main Die is designed to be the most precise and durable die ever made. It uses the latest technology and techniques to ensure that every single component manufactured using it meets the highest standards of quality. At the heart of this revolutionary product is the use of advanced carbide materials that are known for their durability, strength, and resistance to wear and tear.The Shrinkage Rod Carbide Main Die is manufactured using a combination of advanced techniques such as CVD (Chemical Vapor Deposition) Coating, EDM (Electrical Discharge Machining), and Laser Cutting. These techniques help to ensure that the die is perfectly formed and finished, without any defects or imperfections that could affect the accuracy of the final product.The Shrinkage Rod Carbide Main Die is designed to work with a range of different materials, including steel, aluminum, and iron. It is capable of producing complex components with high precision and accuracy, thanks to its advanced design and structure.The company behind this revolutionary product is a leading manufacturer of precision components for the automotive, aerospace, and defense industries. Founded over a decade ago, the company has established itself as a trusted supplier of high-quality components that meet the most demanding standards of quality and performance.In addition to its advanced manufacturing capabilities, the company also boasts a world-class research and development department that is constantly exploring new materials and technologies to improve the performance and reliability of its components. This commitment to innovation has helped the company to stay ahead of its competitors and maintain its position as a leader in the industry.The Shrinkage Rod Carbide Main Die is just one of the many products offered by the company. Its extensive range of precision components includes gears, bearings, shafts, and other critical components that are essential for the smooth operation of machines and equipment in a wide range of industries.The company has a global presence, with manufacturing facilities and sales offices located in different parts of the world. This allows it to serve its customers in a timely and efficient manner, irrespective of their location.In conclusion, the Shrinkage Rod Carbide Main Die is a revolutionary product that is sure to shape the future of manufacturing. With its advanced design, precision engineering, and durability, it is the perfect tool for producing high-quality components with unmatched accuracy and reliability. And with the commitment to innovation and excellence shown by the company behind it, we can be sure that the future of manufacturing is in safe hands.